Preloading paper is not required as the printed sheet will be conveyed to the gantry feeder directly from the printing machine.

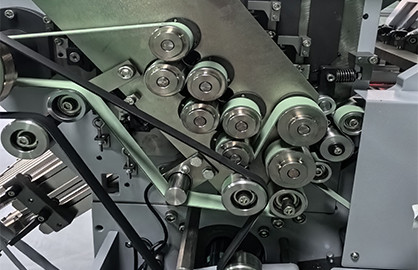

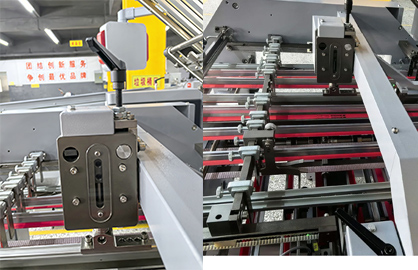

Folding roller adopts belt driving, runs stably and silently,no need for lubricating oil, only need dust removal.

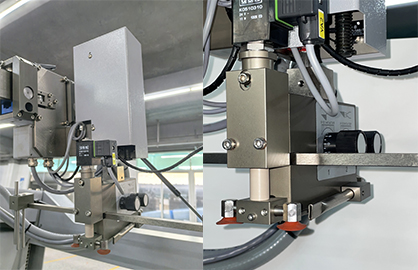

The feeder head is equipped with an extra solenoid valve, which is controlled by the system to make paper suction more stable

Three-hole suction wheel makes paper feeding more stable.

The knife install with a cover to avoid the dust

Large angle computer swing arm for easy operation

Have a lock for the rollers , easy to operate,quickly disassembled

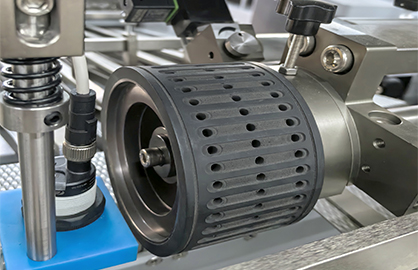

Folding roller adopts the design of imported spiral PU rubber coating, minimizing the risk of wrinkling, creasing, and achieving precise and firm folds.